Short Lead Time for Plastic Insert Molding - Car engine air body turbocharger – Bolok Mold

Short Lead Time for Plastic Insert Molding - Car engine air body turbocharger – Bolok Mold Detail:

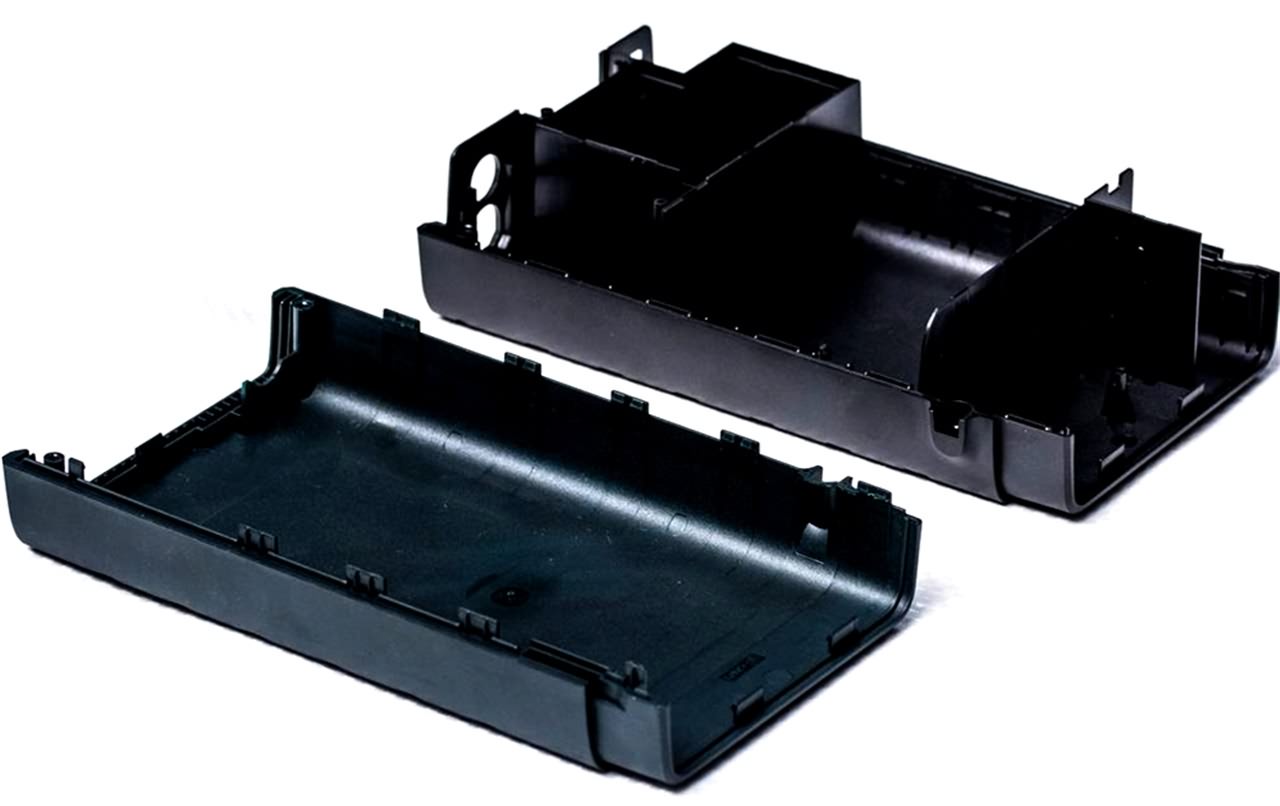

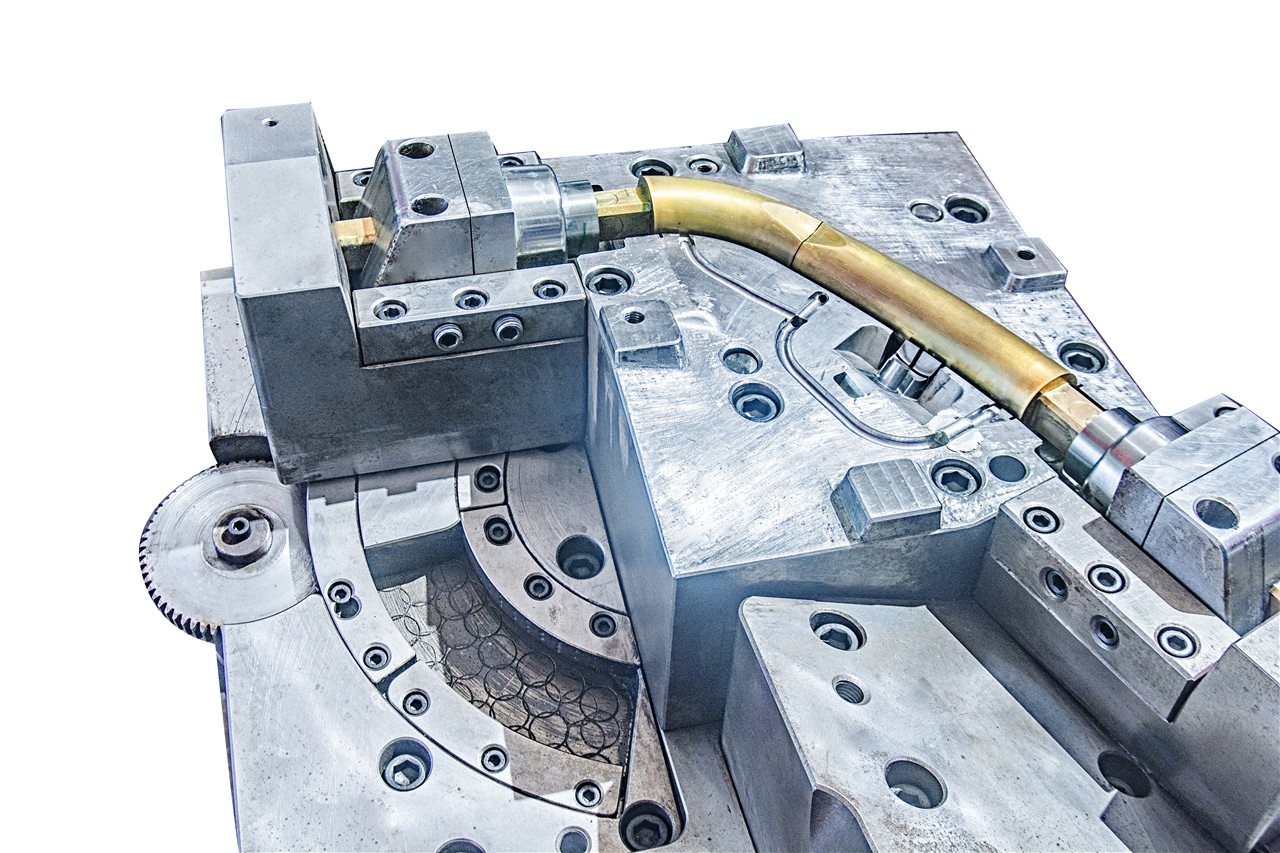

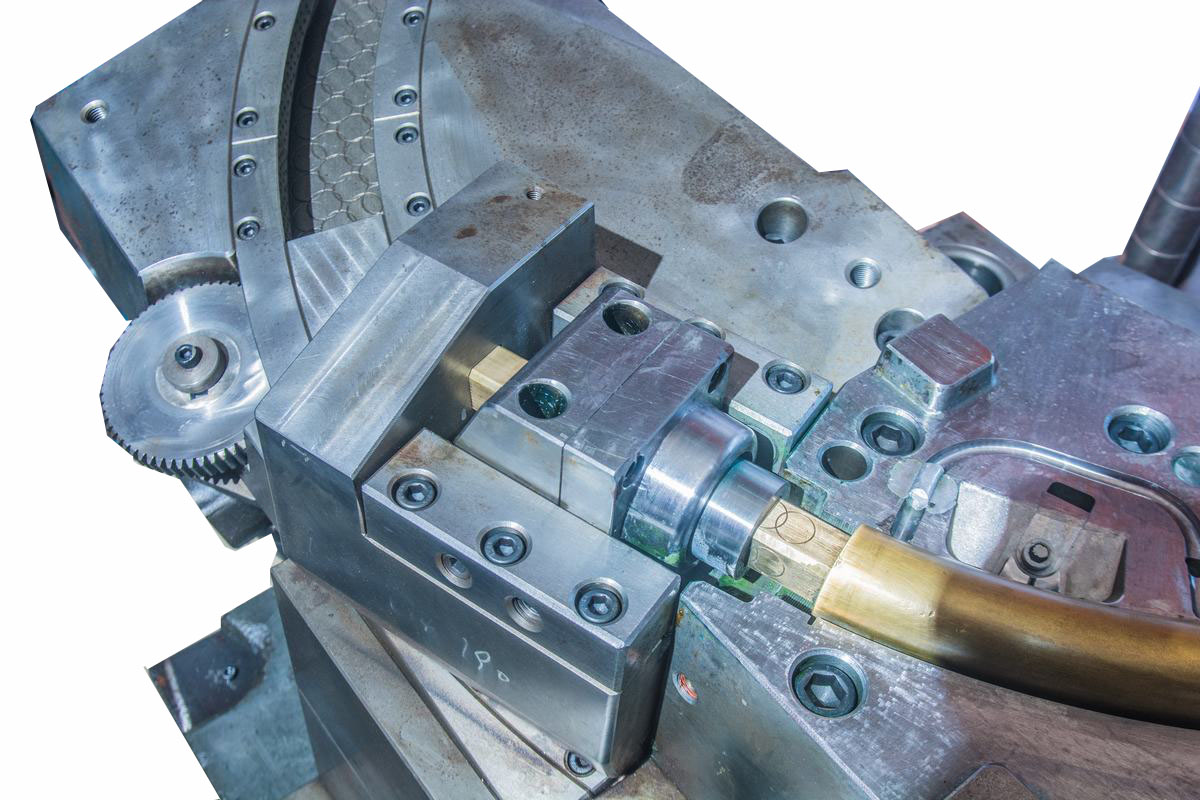

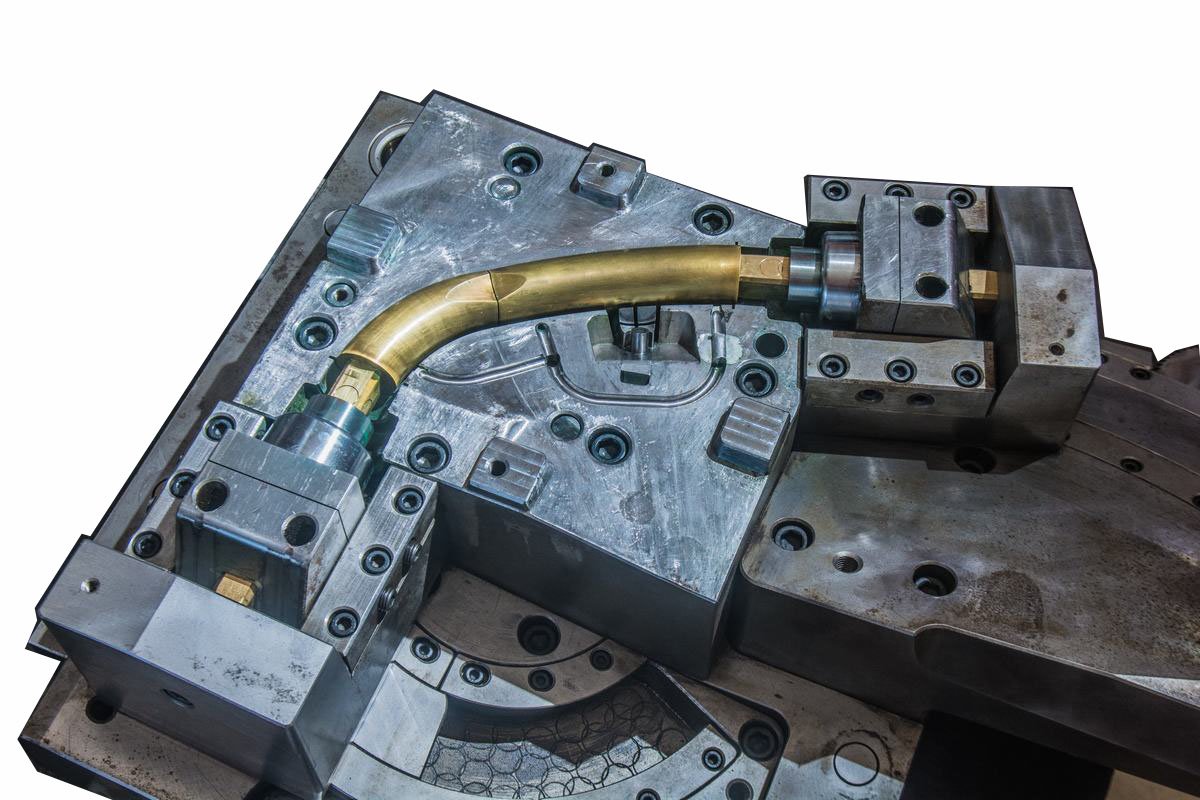

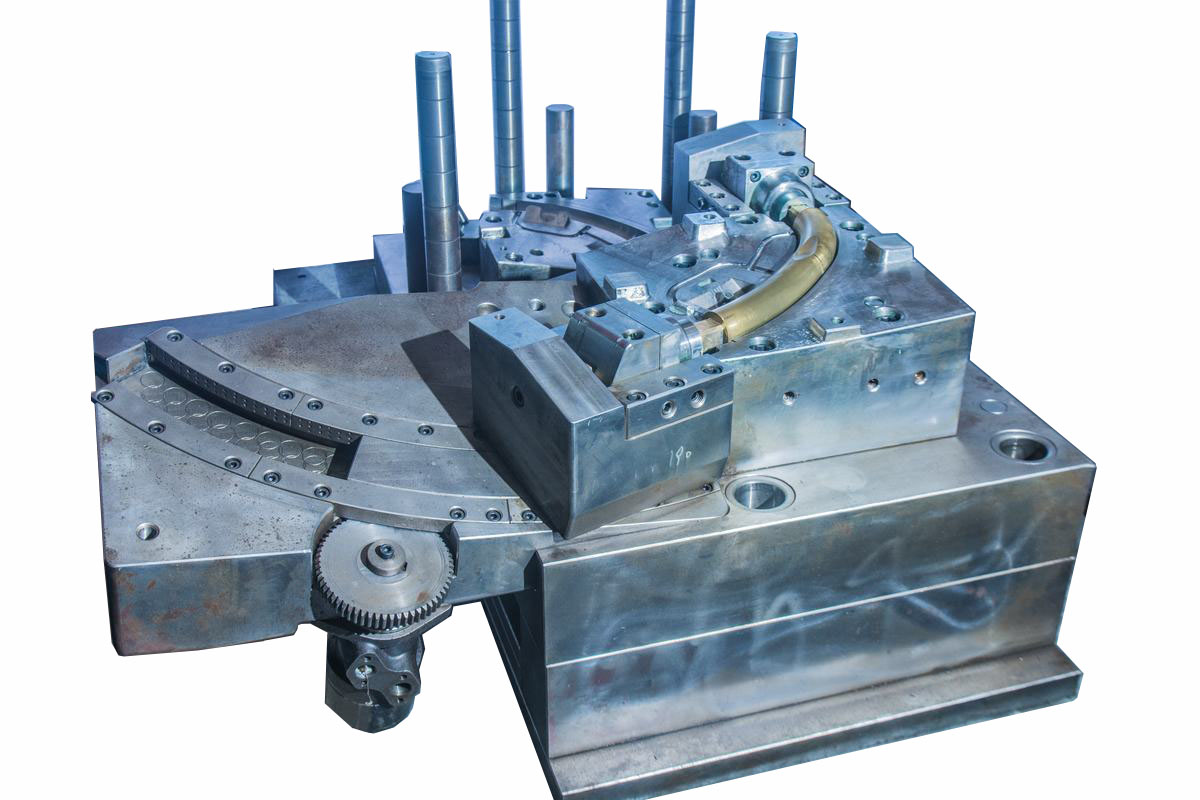

| Part Name | Car engine air body turbocharger |

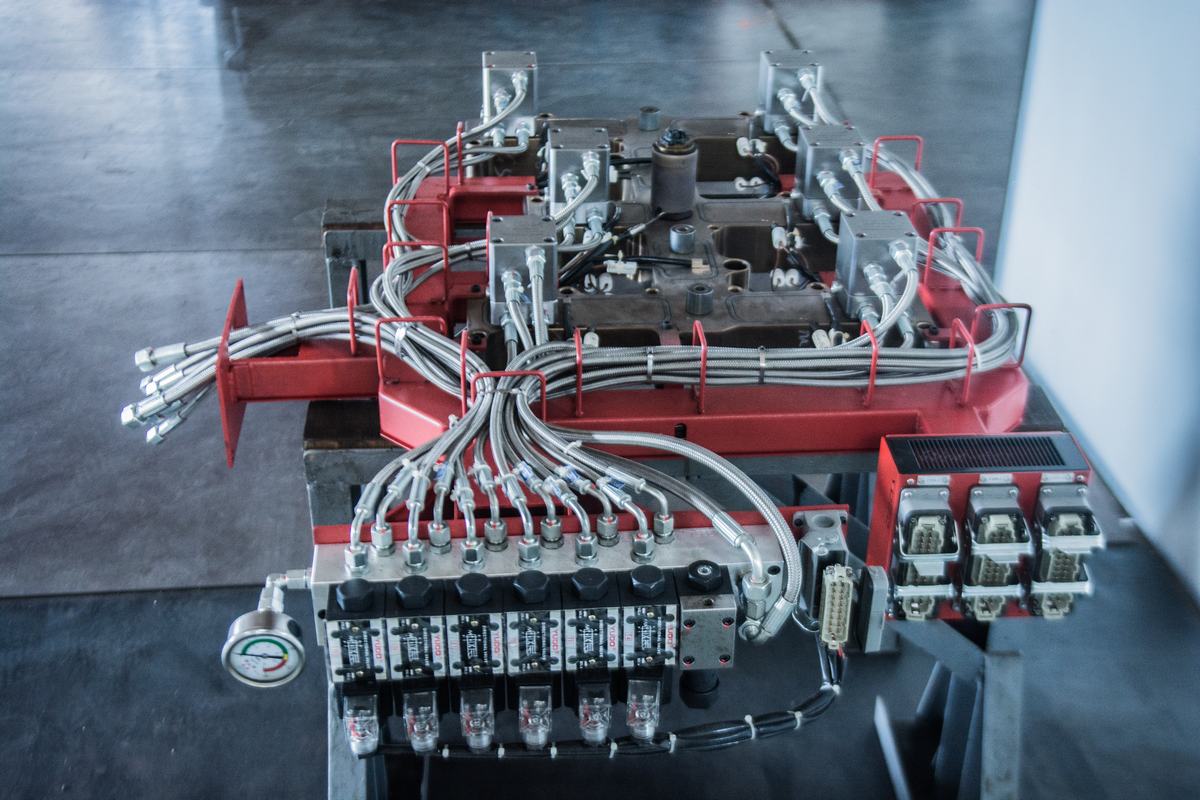

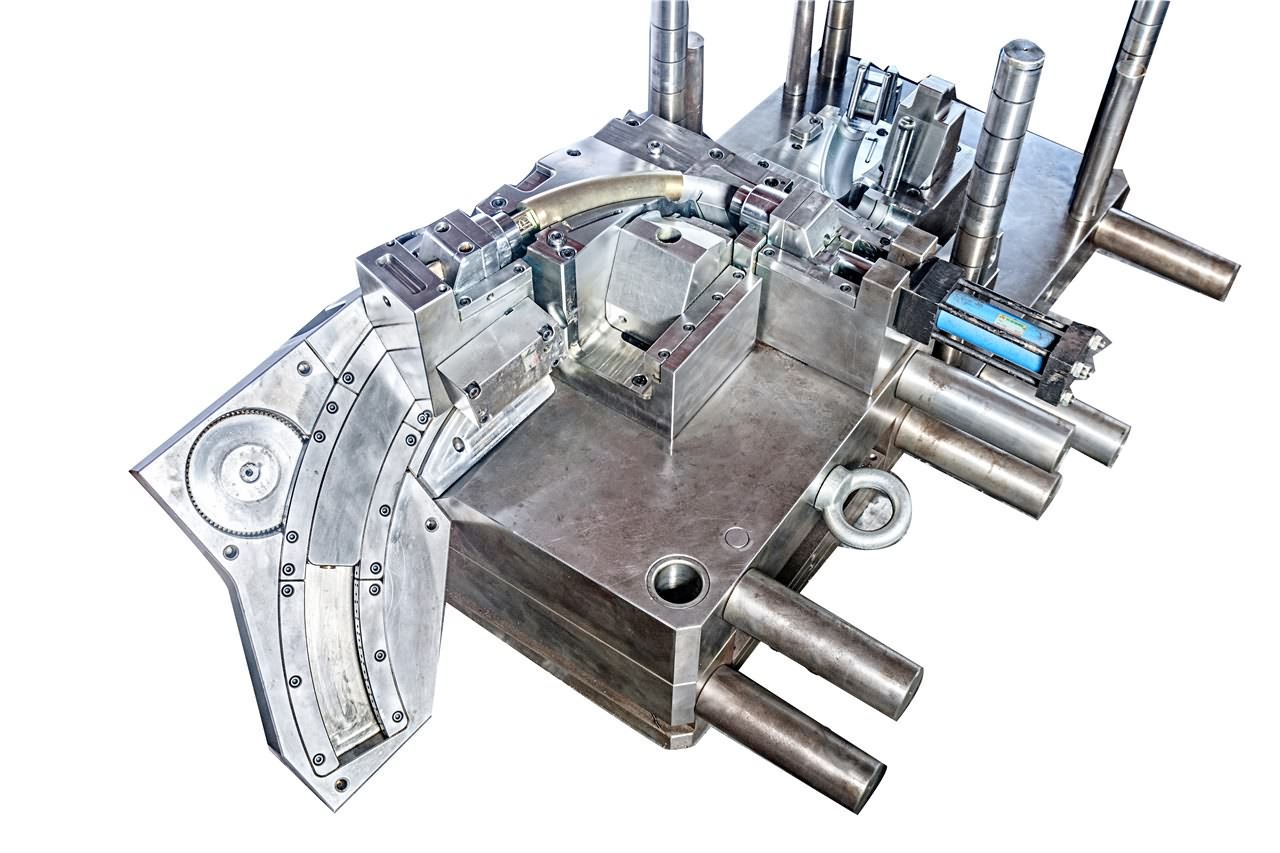

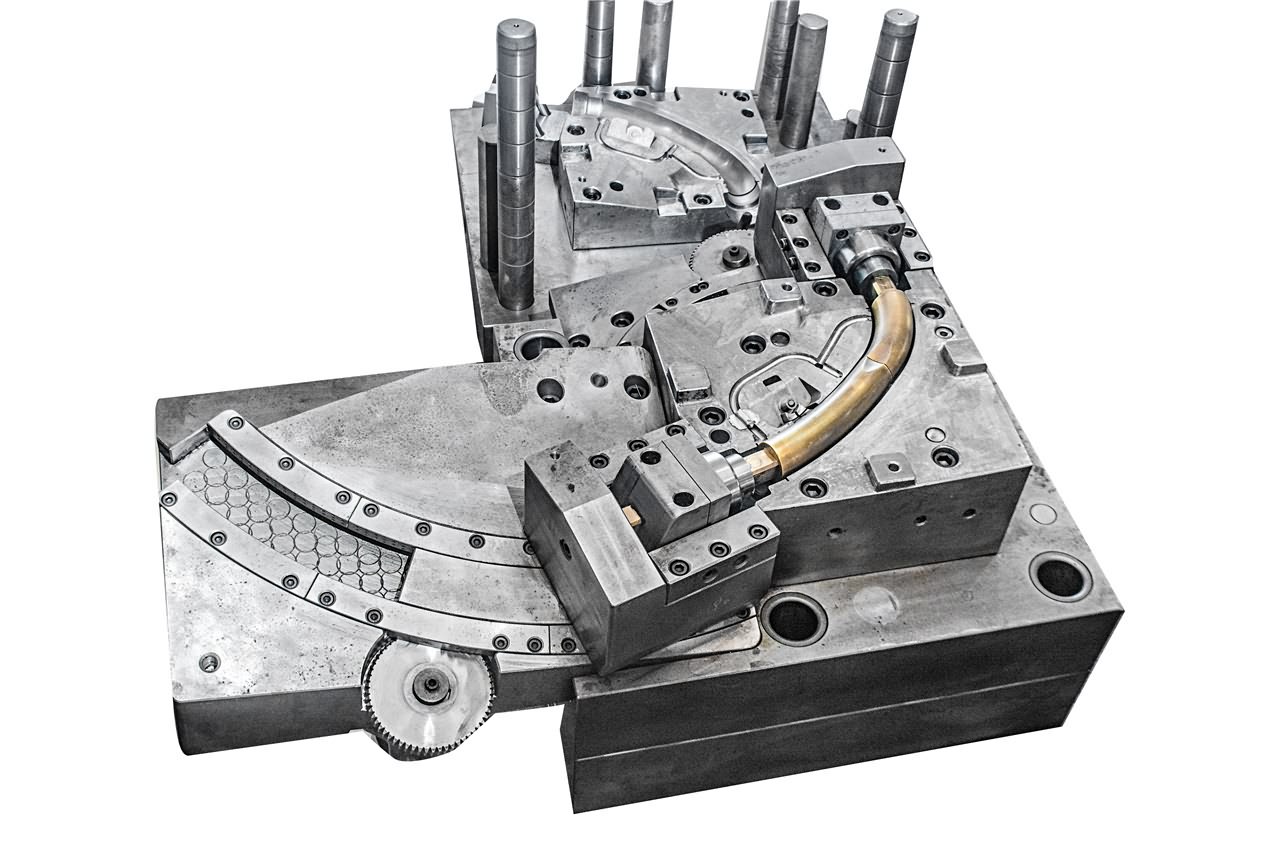

| Product Description | Low-cost rapid prototyping mold, the production cycle is 4 weeks. Arc slider pulling on both sides by hydraulic motor,Straight slider and arc slider secondary pulling,The slider insert is made of beryllium copper, which is cooled quickly to ensure the center of the product. |

| Export country | Germany |

| Product Size | 350X100X150mm |

| Product weight | 236g |

| Material | Zytel 70G30 HSLR Black |

| Finishing | Industrial polish |

| Cavity Number | 1 |

| Mold standard | Metric |

| Mold Size | 450X650X440mm |

| Steel | 718H |

| Mold life | Prototype mold |

| Injection | Cold runner direct on part |

| Ejection | Ejection pin |

| activity | 2 Sliders |

| Injection cycle | 55S |

| Product Features and Application | High-performance engineering plastic pipe instead of aluminum piping or stainless steel to reduce the effects of heat soak and mandrel bends for the best flow.heat dissipation for a long lifetime,Connecting, sealing and transporting.piping is in proper condition, free of cracks and tears |

| Detail | A turbocharger, comprising a driving force of the actuator mechanism to transfer within the turbine housing and a drive shaft rotatably supported by the shaft sleeve, the outside air side end portion of the sleeve with a sealing pieces.The seal includes a seal body made of resin and the embedded metal body of the seal spring recess, the elastic force of the spring by the inner lip seal body is pressed against the inner peripheral surface of the drive shaft.Further, on the end face of the seal body is formed in advance can be provided on the outside air side of the drive shaft member (drive link) of the contact. |

Use

The main function of turbocharging is to increase the air intake of the engine, so as to improve the power and torque of the engine and make the vehicle more powerful. The working principle of turbocharging is: the exhaust gas discharged from the engine exhaust outlet is used as the power to drive the impeller in the turbine chamber. At the same time, the impeller is directly connected with the booster wheel in the booster chamber. One end of the booster chamber is connected with the steam filter, and the other end presses the air sucked from the steam filter into the cylinder of the engine, so as to increase the air in the engine.

Product detail pictures:

Related Product Guide:

We also offer product sourcing and flight consolidation services. We've got our personal factory and sourcing office. We can easily present you with almost every style of merchandise linked to our merchandise range for Short Lead Time for Plastic Insert Molding - Car engine air body turbocharger – Bolok Mold , The product will supply to all over the world, such as: Bangkok, Korea, Gambia, Many products fully conform to the most rigorous of international guidelines and with our first-rate delivery service you will have them delivered at any time and in any place. And because Kayo deals in the entire spectrum of protective equipment, our customers don't need to waste time shopping around.

This is a honest and trustworthy company, technology and equipment are very advanced and the prodduct is very adequate, there is no worry in the suppliment.

Write your message here and send it to us