Professional Design Injection Compression Molding - Medical Device Components Housing – Bolok Mold

Professional Design Injection Compression Molding - Medical Device Components Housing – Bolok Mold Detail:

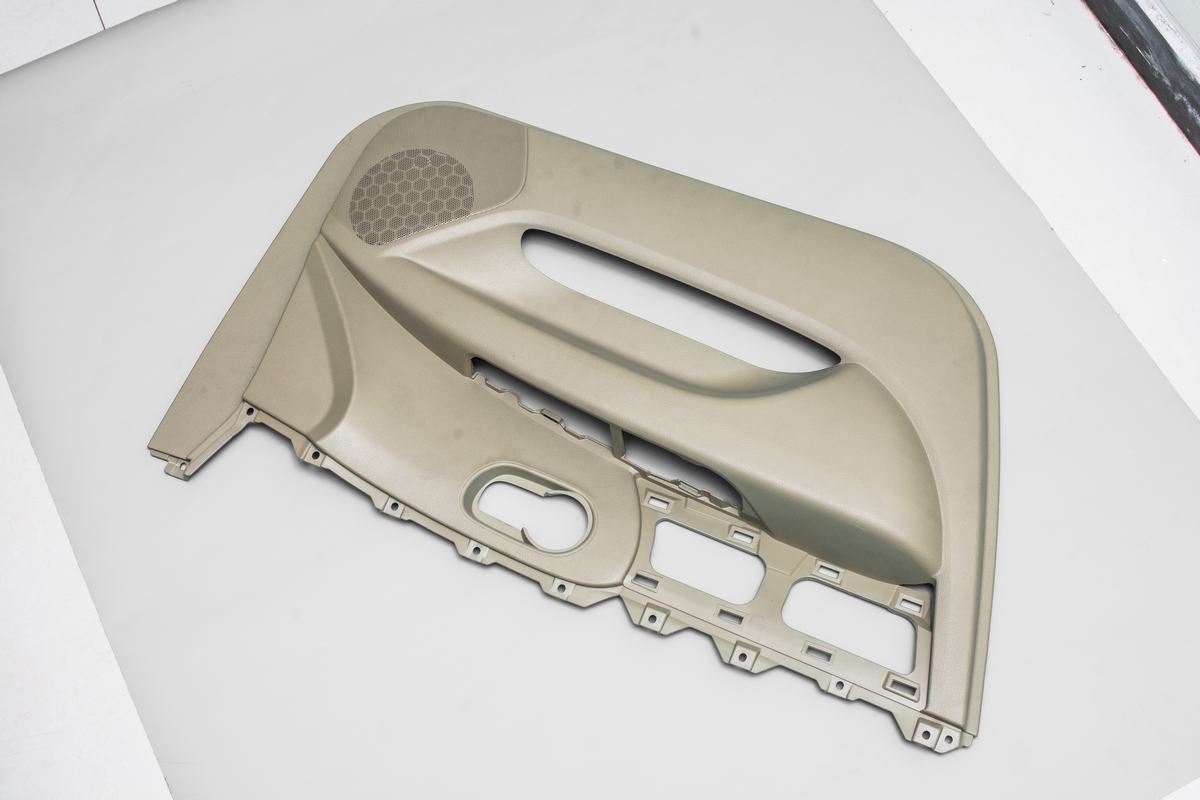

| Part Name | Medical Device Components Housing |

| Product Description | We manufacture medical enclosures that meet today’s strict industry requirements, such as large medical equipment enclosures such as MR and home medical equipment enclosures such as blood glucose monitors. Comply with FDA standards. |

| Export country | USA |

| Product Size | 150X80X60 |

| Product weight | 36g |

| Material | PA6 GF30 |

| Finishing | VDI 32 |

| Cavity Number | 1+1 |

| Mold standard | HASCO |

| Mold Size | 350X350X360MM |

| Steel | 1.2736 |

| Mold life | 5,000,000 |

| Injection | Cold runner flat gate |

| Ejection | Ejection pin |

| activity | 4 sliders |

| Injection cycle | 30S |

| Product Features and Application | medical device manufacturing |

Detail

This is the shell of a blood glucose monitor, which is exported to the United States.Injection with cold runner and flat gate,The service life of the die is 500000 times.The shell is made of PA6 plastic material and 30% glass fiber.

Material

The material of this product is PA6 plastic material plus 30% glass fiber.

The basic formula of PA6GF30:

|

PA6GF30 |

Proportion(%) |

|

PA6 new material (2.75) |

70 |

|

Long glass fiber (988A/635B/5301HP) |

30 |

|

Antioxidant 225/1010+168 |

0.3/0.2+0.2 |

|

Lubricant (EBS/PETS) |

0.3 |

|

Remark |

According to the actual situation, customers can adjust the application of various glass fibers to adjust the hue of the finished product |

Under the influence of covid-19, we also cooperate with Medical Devices Co., Ltd. to produce molds for the shells of medical instruments and treatment equipment.It is also due to the cooperation with these companies that we can obtain enough epidemic prevention substances (such as N95 masks, protective clothing, nucleic acid reagents, etc.) at a critical juncture to ensure the normal operation of the company.

Product detail pictures:

Related Product Guide:

To be the stage of realizing dreams of our employees! To build a happier, more united and more professional team! To reach a mutual benefit of our customers, suppliers, the society and ourselves for Professional Design Injection Compression Molding - Medical Device Components Housing – Bolok Mold , The product will supply to all over the world, such as: Poland, Poland, Dubai, Our product quality is one of the major concerns and has been produced to meet the customer's standards. "Customer services and relationship" is another important area which we understand good communication and relationships with our customers is the most significant power to run it as a long term business.

We are really happy to find such a manufacturer that ensuring product quality at the same time the price is very cheap.