Personlized Products Direct Injection Molding - SMALL AUTOMOBILE AIR BODY TURBOCHARGER – Bolok Mold

Personlized Products Direct Injection Molding - SMALL AUTOMOBILE AIR BODY TURBOCHARGER – Bolok Mold Detail:

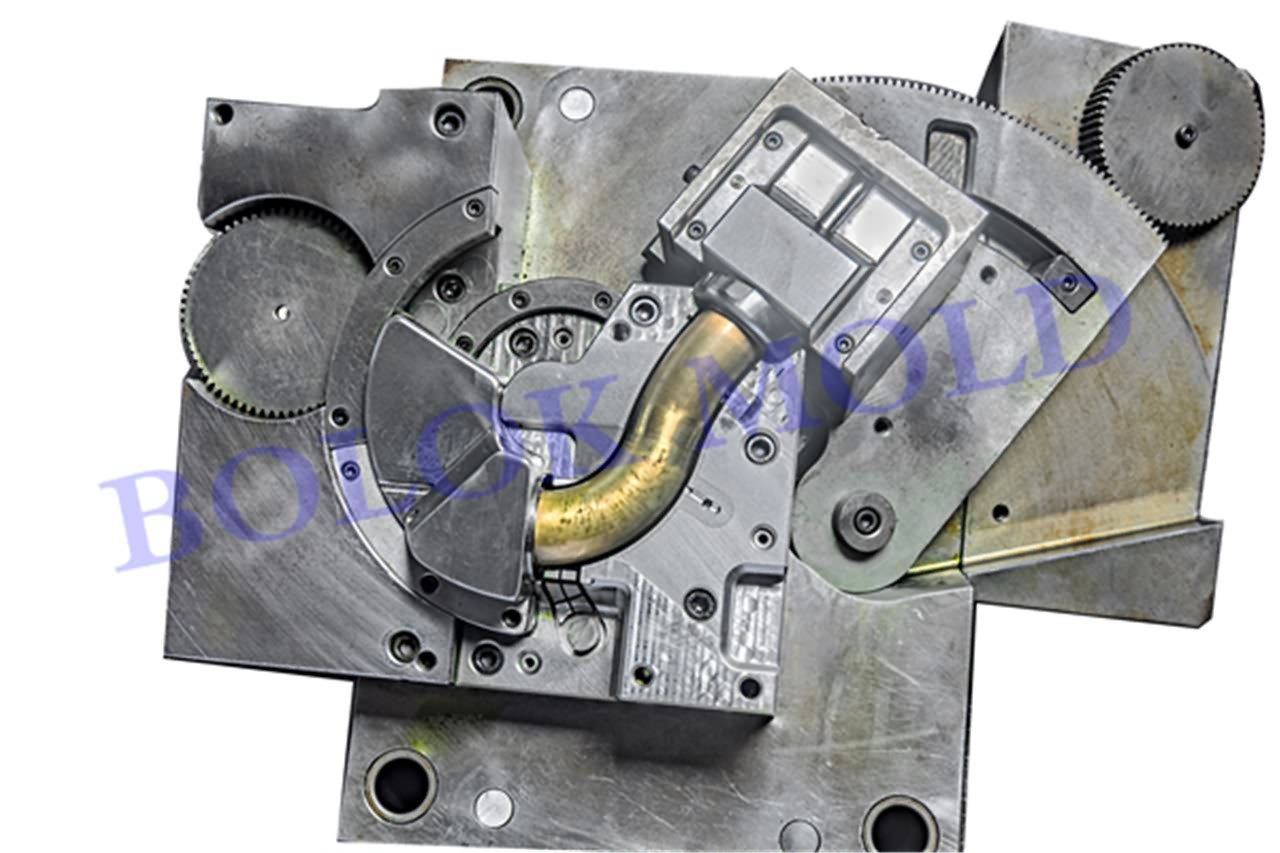

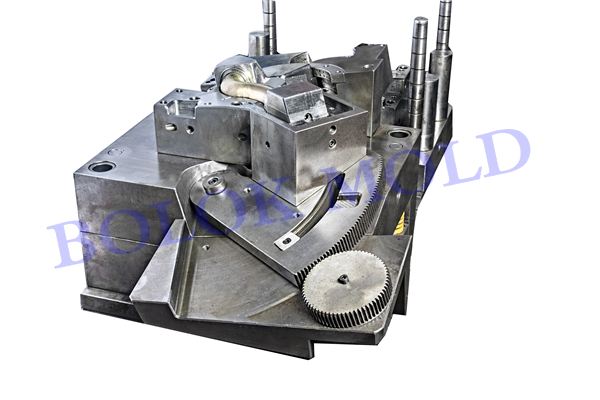

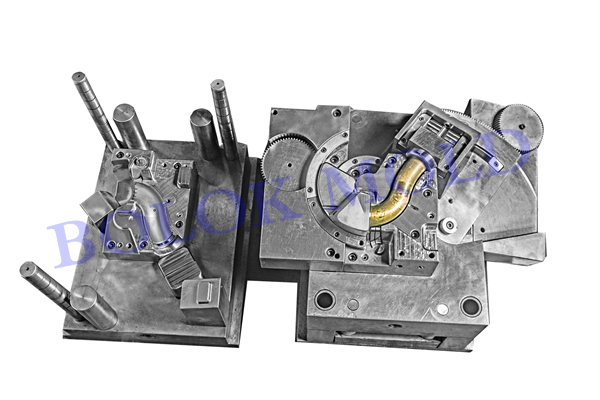

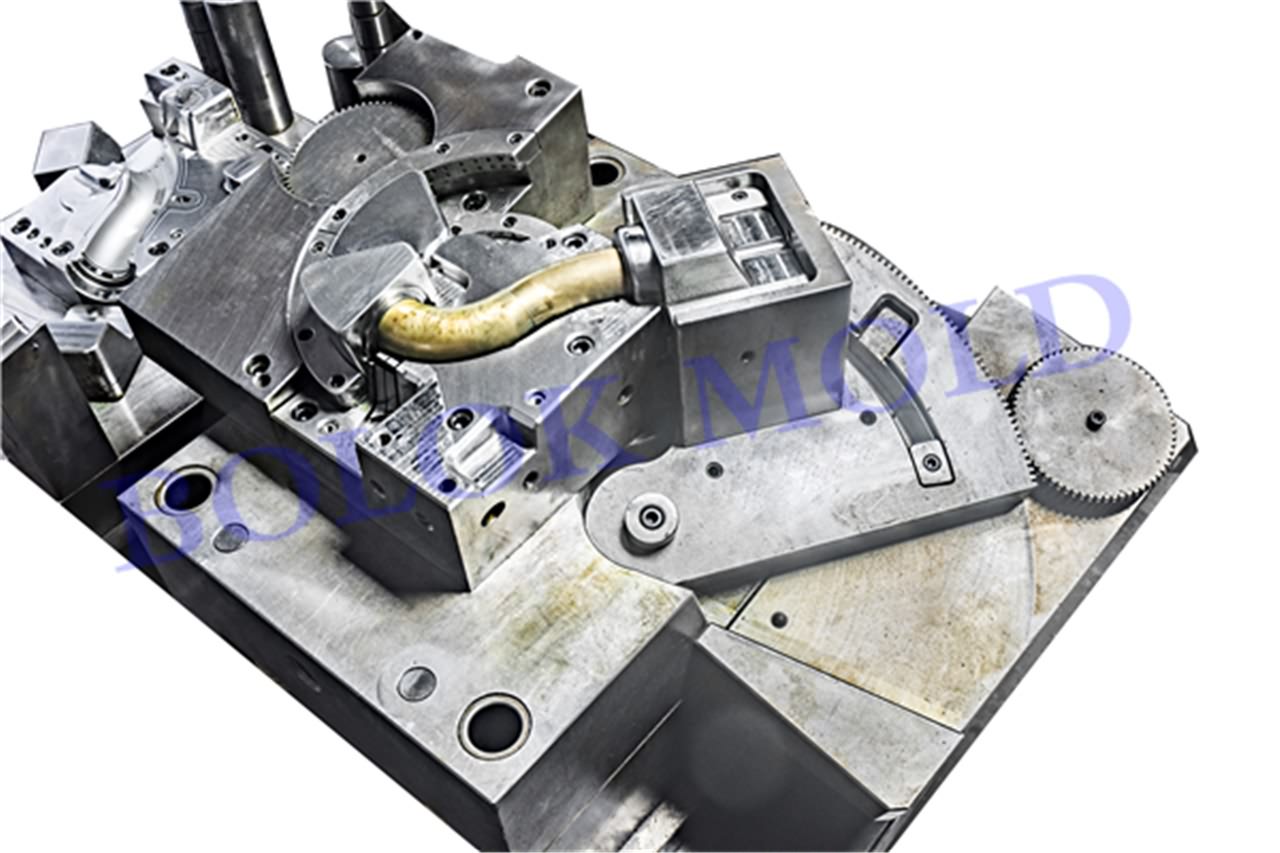

| Part Name | AIR BODY TURBOCHARGER |

| Product Description | Low-cost rapid prototyping mold, the production cycle is 4 weeks. Arc slider pulling on both sides by hydraulic motor,Straight slider and arc slider secondary pulling,The slider insert is made of beryllium copper, which is cooled quickly to ensure the center of the product. |

| Export country | Germany |

| Product Size | 350X100X150mm |

| Product weight | 236g |

| Material | Zytel 70G30 HSLR Black |

| Finishing | Industrial polish |

| Cavity Number | 1 |

| Mold standard | Metric |

| Mold Size | 450X650X440mm |

| Steel | 718H |

| Mold life | Prototype mold |

| Injection | Cold runner direct on part |

| Ejection | Ejection pin |

| activity | 2 Sliders |

| Injection cycle | 55S |

| Product Features and Application | High-performance engineering plastic pipe instead of aluminum piping or stainless steel to reduce the effects of heat soak and mandrel bends for the best flow.heat dissipation for a long lifetime,Connecting, sealing and transporting.piping is in proper condition, free of cracks and tears |

| Detail | Centrifugal compressor and turbine are combined into a whole, which is called turbocharger. The main difference between it and gas turbine is that the unit is not equipped with combustion chamber and corresponding system. The turbine works by using the exhaust energy of reciprocating internal combustion engine, and the compressed air provided by its centrifugal compressor is used as the charge of reciprocating internal combustion engine. In the turbocharger, the compressor impeller and turbine are assembled on the same rotating shaft, which is called rotor. There are seals and thrust plates placed on the same rotor shaft and rotating together.Rotor is the key component of turbocharger. In addition, the turbocharger also includes bearing device, lubrication and cooling system, sealing and heat insulation device, compressor housing, intermediate housing, turbine housing and other fixings necessary for normal operation.This product is a Prototype mold, It can help factories produce products quickly and at low cost.

|

Mold Type

This product is a Prototype mold, It can help factories produce products quickly and at low cost.

What is Prototype mold?

Prototype mold is a term familiar to most designers and manufacturers because it is related to the process of turning a concept into reality. Usually, when industrial or product designers have a concept of a product, they will go through various stages, from a simple idea to a more realistic concept, and express the product with tangible things, which represents the appearance of the product after manufacturing. Although the prototype mold is used to create a representative object, which fully reflects the designer’s ideas, it is different from the prototype mold in the sense of production mold, which is far lower than the cost and permanence of production mold. With the emergence of 3D printers, some types of prototype molds have become obsolete. The way the prototype mold is created allows any further modifications to the product, because the prototype mold is only used when the product is still fine tuned. For example, a designer has a concept of a table lamp. He will first use a mold to see what the finished product will look like. At this stage, the designer can add any additional decoration to the product to make it conform to the concept of the product. Assuming that the sample results of the prototype die are not satisfactory, the designer will modify the die several times to produce something more like the designer’s mind. This is different from the production mold, because the production mold is used for mass production and lasts longer than the prototype mold, because at this point, the goal is not so. Fine tuning the design rather than putting it into full production. One of the reasons why designers choose to use the prototype mold before using the production mold is the complexity of the concept, This may require a lot of attention to detail to achieve the design. The prototype design phase will consist of several progressive steps until satisfactory results are obtained. According to the complexity of the design, some designers can create their own molds or hire the services of prototype developers.

Product detail pictures:

Related Product Guide:

"Control the standard by the details, show the power by quality". Our firm has strived to establish a extremely efficient and stable employees crew and explored an effective excellent command method for Personlized Products Direct Injection Molding - SMALL AUTOMOBILE AIR BODY TURBOCHARGER – Bolok Mold , The product will supply to all over the world, such as: USA, Johor, Cancun, The president and all the company members would like to provide professional products and services for customers and sincerely welcome and cooperate with all native and foreign customers for a bright future.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.