OEM China Plastic Injection Mold Components - Large-capacity outdoor power bank shell – Bolok Mold

OEM China Plastic Injection Mold Components - Large-capacity outdoor power bank shell – Bolok Mold Detail:

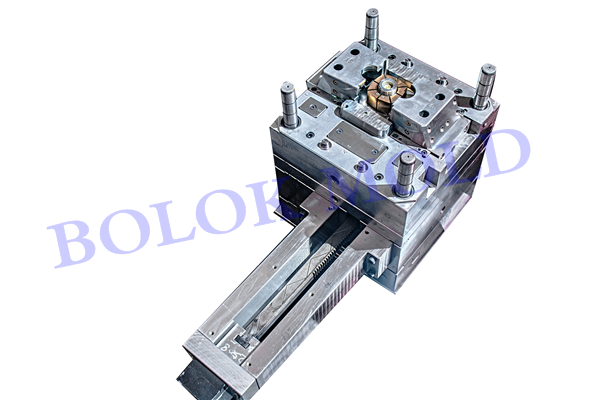

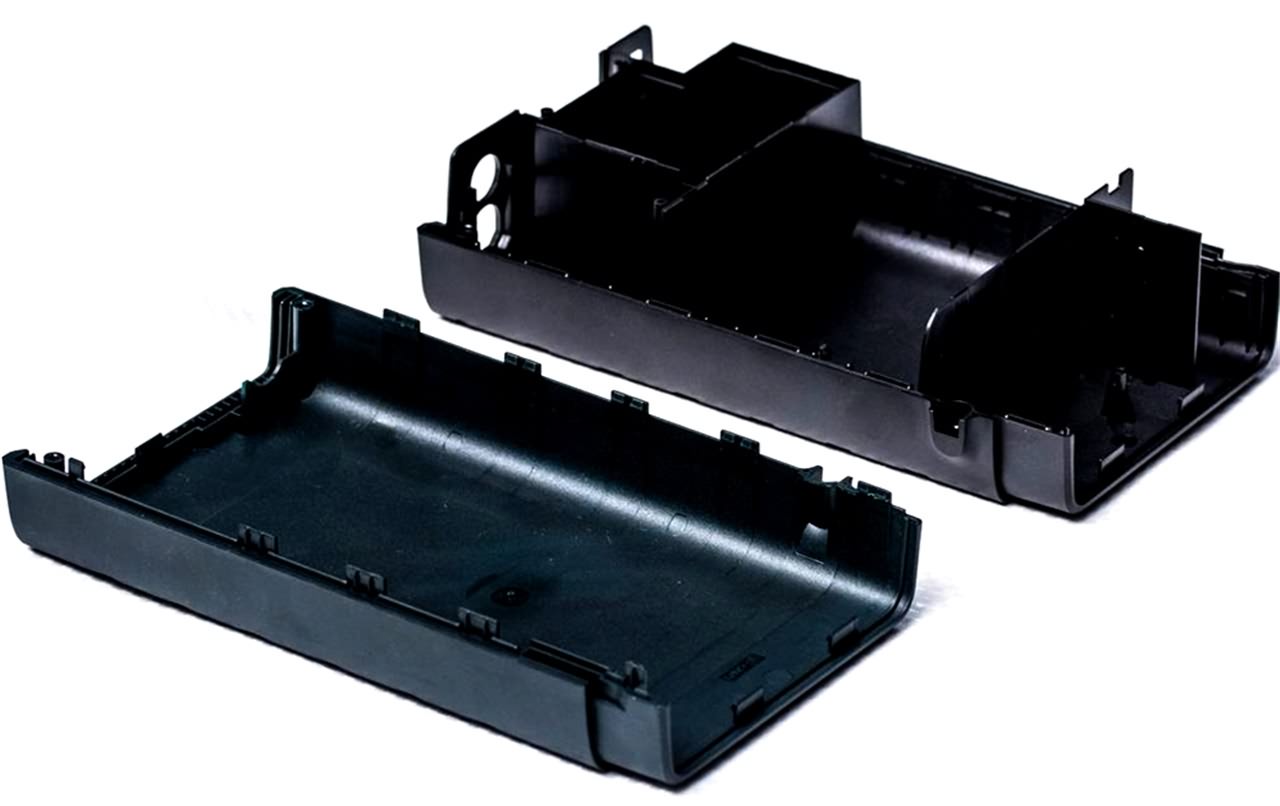

| Part Name | Large-capacity outdoor power bank shell |

| Product Description | Outdoor large-capacity power bank, esistant to impact and drop.Meets UL217 and ULC531 specificationsCertifications: FCC, IC, UL217, ULC531, CSFM |

| Export country | USA |

| Material | ABS V0 |

| Finishing | VDI 32 |

| Cavity Number | 1+1 |

| Mold standard | MISUMI |

| Mold Size | 350X400X390MM |

| Steel | SUS 420 J2 |

| Mold life | 1,000,000 |

| Injection | Cold runner Sub gate |

| Ejection | Ejection pin |

| activity | 3 sliders |

| Injection cycle | 45S |

| Product Features and Application | Outdoor large-capacity power bank, in line with American FCC and UL2056 certification.Resistant to impact and drop. |

Useage

Mobile power supply is a portable charger that can be carried by individuals and can store electric energy. It is mainly used to charge consumer electronic products such as handheld mobile devices (such as wireless phones and laptops), especially when there is no external power supply. Its main components include: batteries used for electric energy storage, circuits for stabilizing output voltage (DC-DC converter), and most mobile power supplies are equipped with chargers to charge as built-in batteries.

Material

There are three commonly used shell materials for mobile power supply shell: aluminum alloy, hardware + plastic and plastic. The alloy material has good heat dissipation performance, but it is difficult to manufacture and the price is not low. The shell made of plastic material or hardware + plastic material is mainly made of plastic material, the heat dissipation effect is not as good as aluminum alloy material, and the requirements for fire resistance are very high. The material selection of hardware and plastic can enhance the sense of hierarchy of products and make the original non creative products look less than a single stereotype. At the same time, this matching method can also create higher quality design

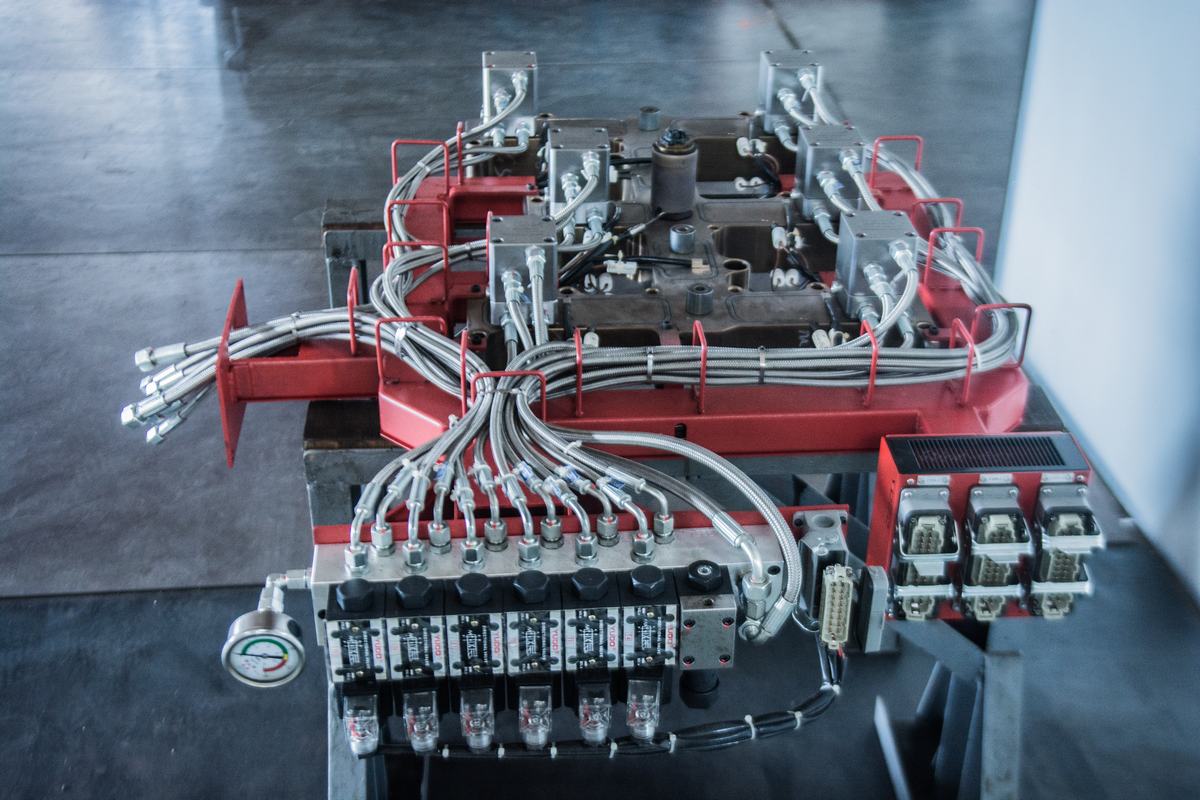

Product detail pictures:

Related Product Guide:

It is a great way to further improve our products and repair. Our mission is always to create innovative products to prospects with a superior expertise for OEM China Plastic Injection Mold Components - Large-capacity outdoor power bank shell – Bolok Mold , The product will supply to all over the world, such as: Belarus, Durban, Barbados, With high quality, reasonable price, on-time delivery and customized & customized services to help customers achieve their goals successfully, our company has got praise in both domestic and foreign markets. Buyers are welcome to contact us.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.