Factory source Custom Molded Plastic Parts - PMMA and PC High Transparent Plastic Parts – Bolok Mold

Factory source Custom Molded Plastic Parts - PMMA and PC High Transparent Plastic Parts – Bolok Mold Detail:

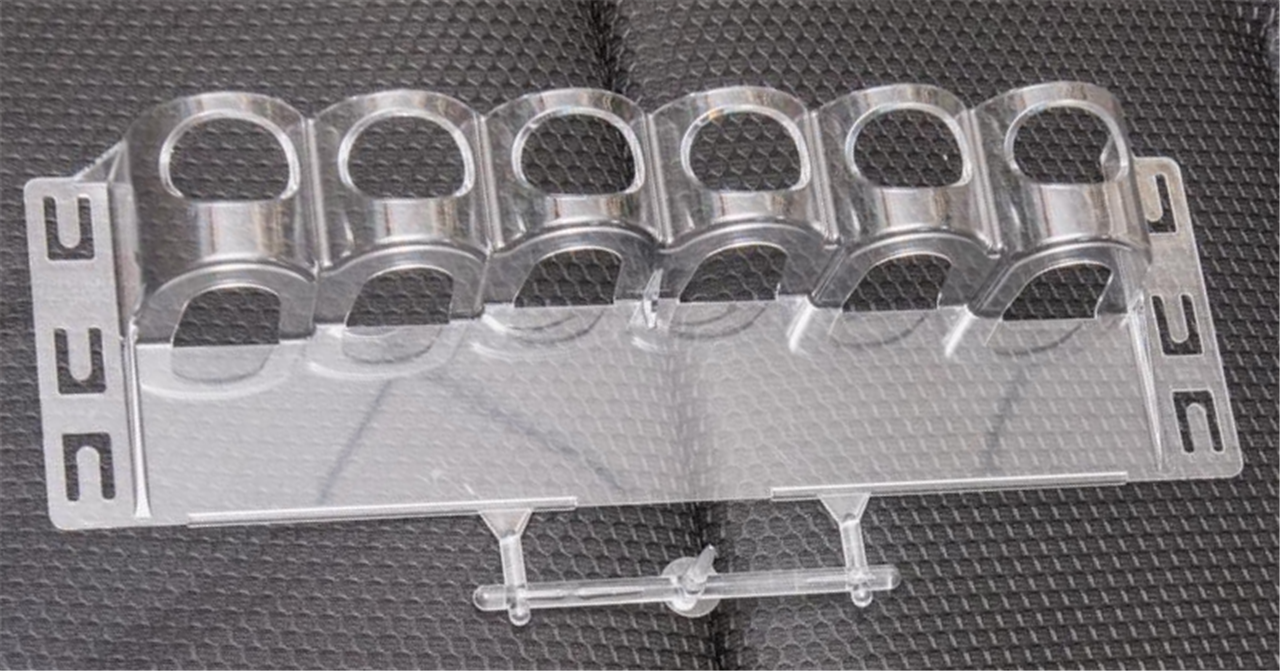

| Part Name | PMMA and PC High Transparent Plastic Parts |

| Product Description | highly transparent Widely used in Packaging, Building & Construction, Electrical & Electronics, Automotive, Consumer Goods, Healthcare, Others (Aerospace, Agriculture). Polymer type include PET,PVC,PP,PS,PC,PMMA,Others (Polyamide, ABS & SAN, Polyethylene, TPU) Mold finish for mirror or optical finishes |

| Export country | France |

| Material | PC |

| Finishing | Mirror polish |

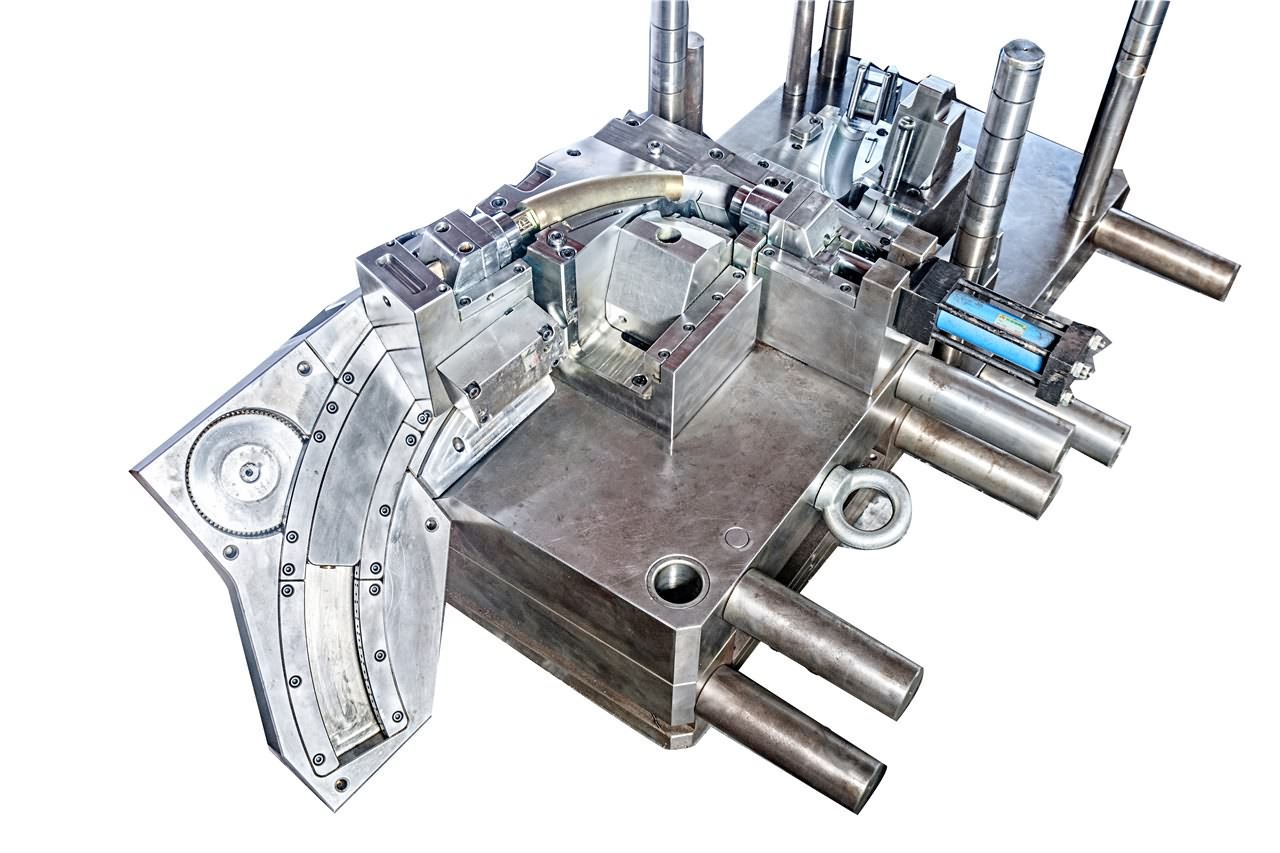

| Cavity Number | 1+1 |

| Mold standard | HASCO |

| Mold Size | |

| Steel | S136H |

| Mold life | 500000 |

| Injection | Cold runner flat gate |

| Ejection | Ejection pin |

| Injection cycle | 30S |

| Product Features and Application | High temperature resistance, excellent wear resistance, high temperature steam resistance, high temperature, high frequency and high voltage electrical properties.UL94 V0, V2 and 5VA ratings and is RoHS compliant. And an unreinforced general purpose grade offering high heat resistance, high strength and modulus and broad chemical resistance up to high temperatures. |

Technology

The types of transparent plastic materials commonly used in the market are: polymethyl methacrylate (acrylic or plexiglass PMMA plastic), polycarbonate (PC plastic), polyethylene terephthalate (PET), transparent nylon, AS (Acrylonitrile-styrene copolymer) etc. Among them, the three plastics that we are most exposed to are PMMA, PC and AS.

1. The properties of transparent plastics: firstly, transparent plastics must have high transparency, and secondly they must have certain strength and wear resistance, impact resistance, heat resistance, chemical resistance, and water absorption. In use, it satisfies the requirements of transparency and has stable performance.

2. Process characteristics of PMMA. PMMA has high viscosity and poor fluidity. Therefore, high material temperature and high injection pressure must be used for injection molding. The influence of injection temperature is greater than injection pressure, but the increase in injection pressure will help improve the shrinkage rate of the product. Poor impact resistance, poor wear resistance, easy to scratch, easy to brittle, so the mold temperature should be increased, and the condensation process should be improved to overcome these defects.

3. Process characteristics of PC. PC has high viscosity, high melting temperature and poor fluidity, and its manufacturability is not as good as PMMA. The injection pressure has little effect on the fluidity, but due to the high viscosity, the injection pressure is still higher. Correspondingly, in order to prevent internal stress, the pressure holding time should be as short as possible. The shrinkage rate is large, the size is stable, but the internal stress of the product is large, and it is easy to crack.

4. Process characteristics of PET. PET molding temperature is high, and the material temperature adjustment range is narrow (260-300°C), but after melting, it has good fluidity, so the manufacturability is poor, and it is often necessary to add anti-spreading devices in the nozzle. The mechanical strength and performance are not high after injection, and the performance must be improved through the stretching process and modification.

Product detail pictures:

Related Product Guide:

We know that we only thrive if we will guarantee our combined cost competiveness and high-quality advantageous at the same time for Factory source Custom Molded Plastic Parts - PMMA and PC High Transparent Plastic Parts – Bolok Mold , The product will supply to all over the world, such as: Thailand, Singapore, Sacramento, Our product quality is one of the major concerns and has been produced to meet the customer's standards. "Customer services and relationship" is another important area which we understand good communication and relationships with our customers is the most significant power to run it as a long term business.

The sales person is professional and responsible, warm and polite, we had a pleasant conversation and no language barriers on communication.