factory Outlets for Plastic Prototype Service - PP Copo plastic Molette pied F2 – Bolok Mold

factory Outlets for Plastic Prototype Service - PP Copo plastic Molette pied F2 – Bolok Mold Detail:

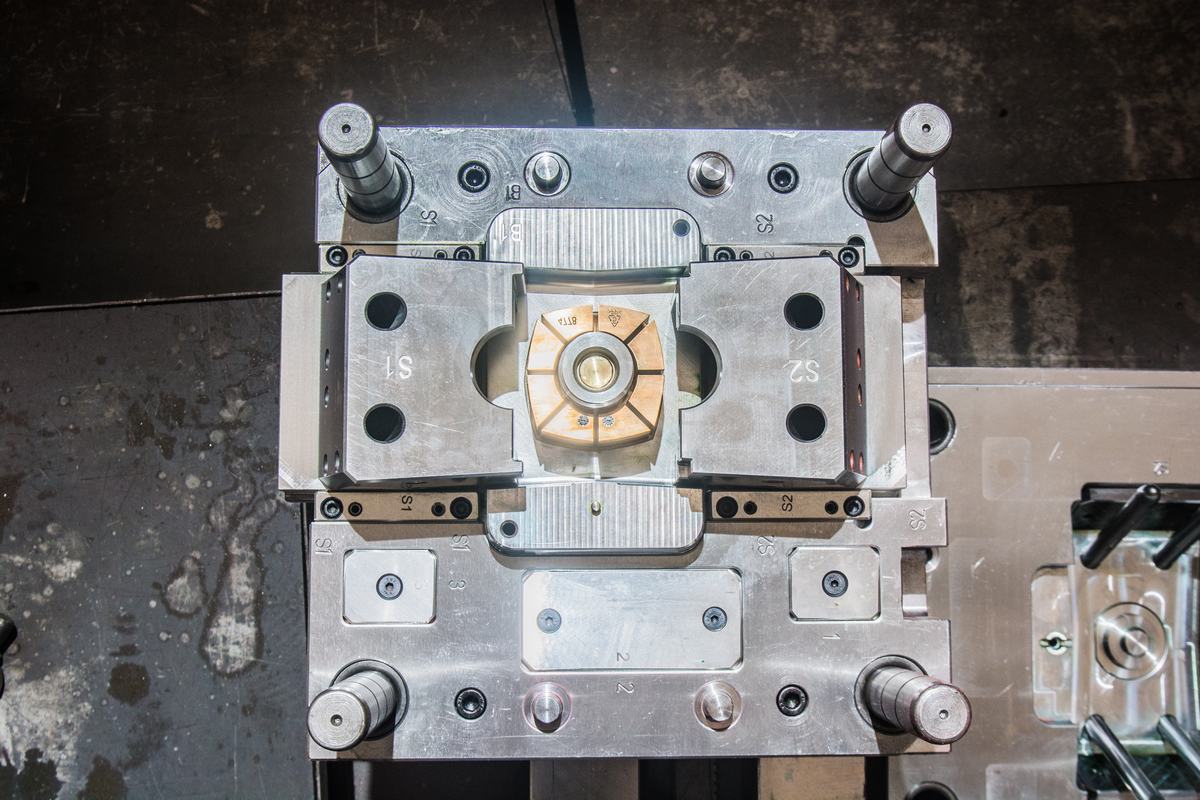

| Part Name | PP Copo plastic Molette pied F2 |

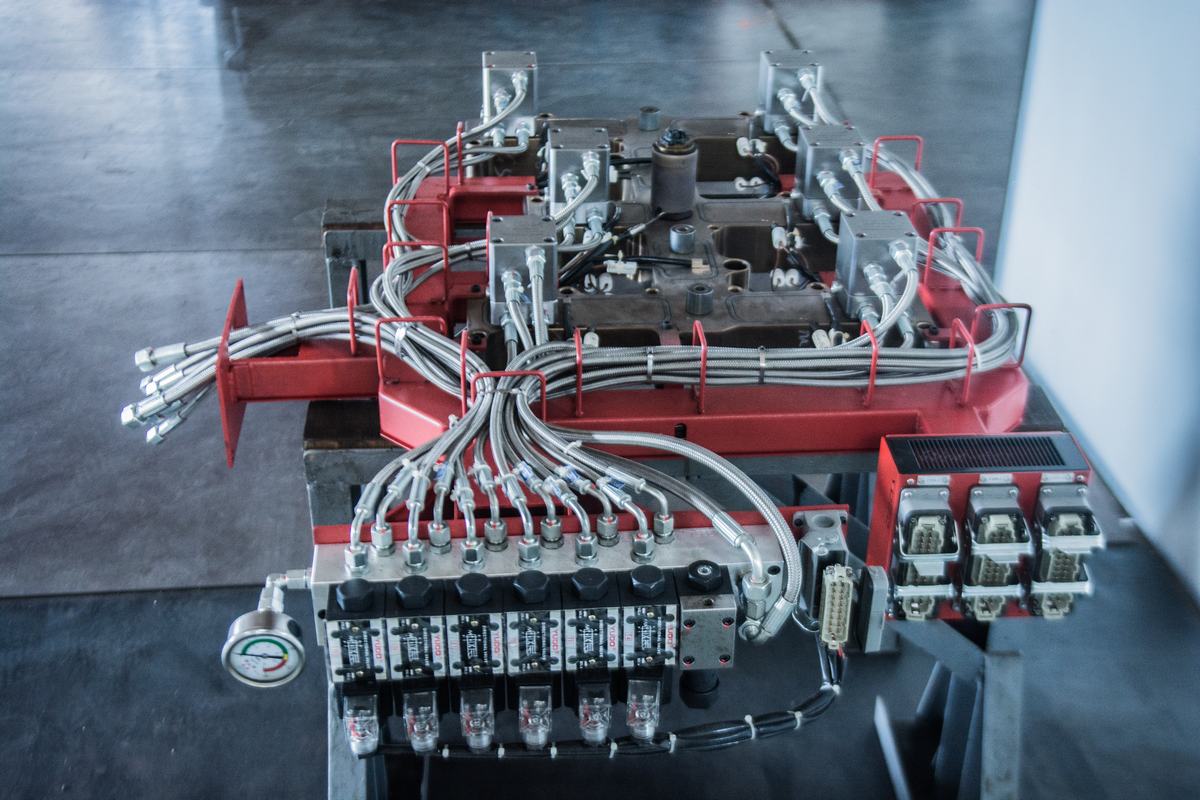

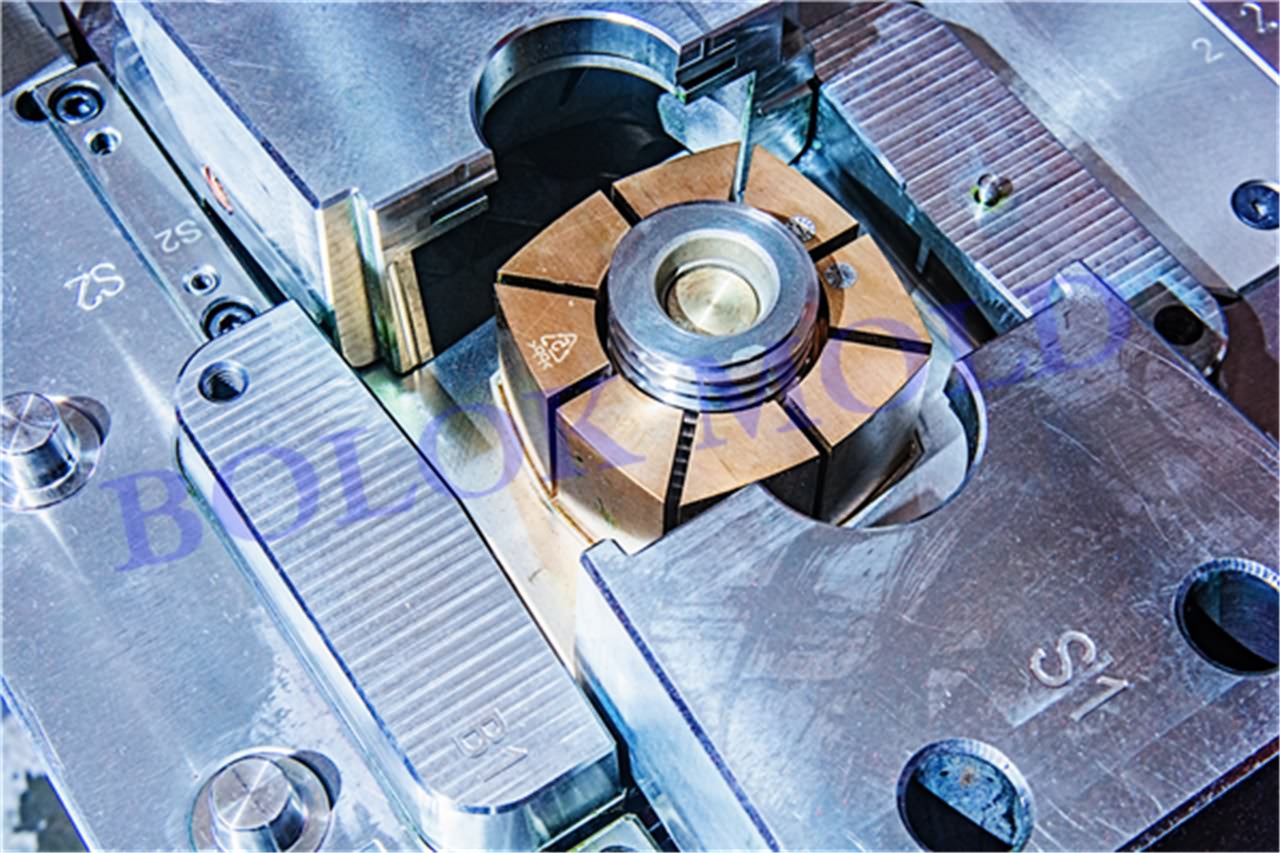

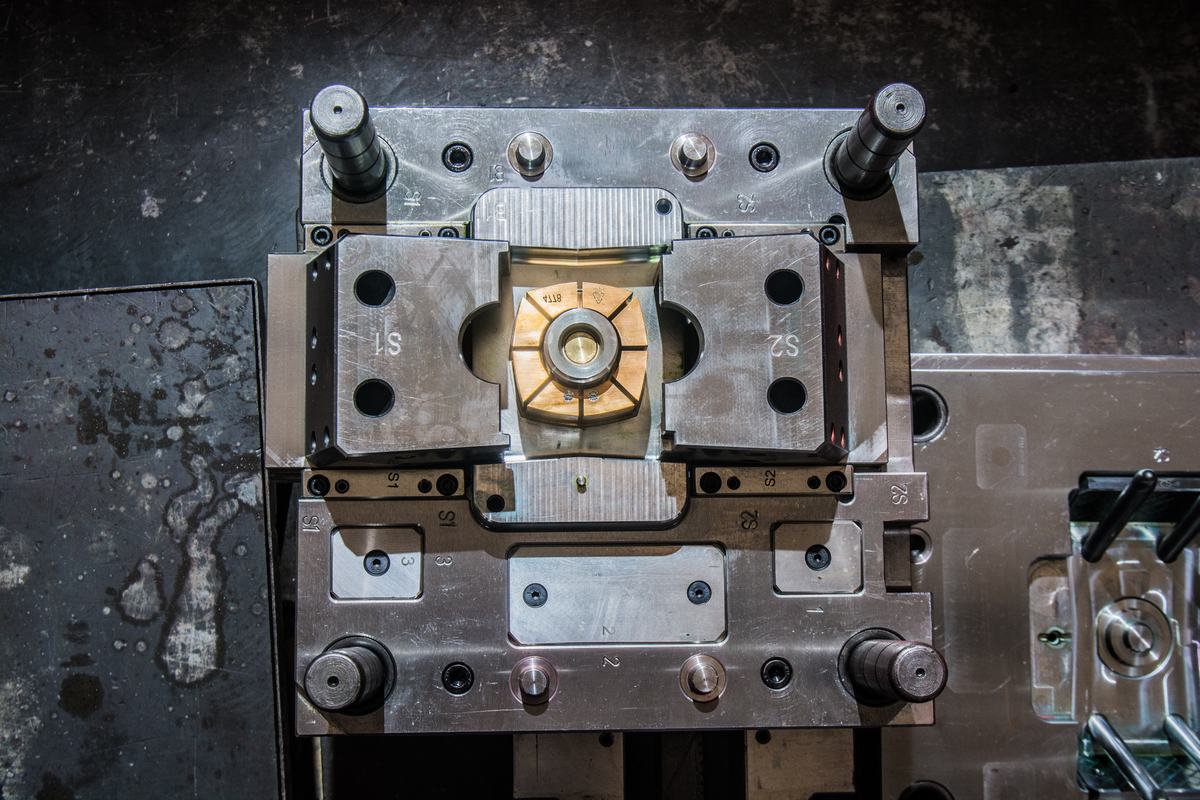

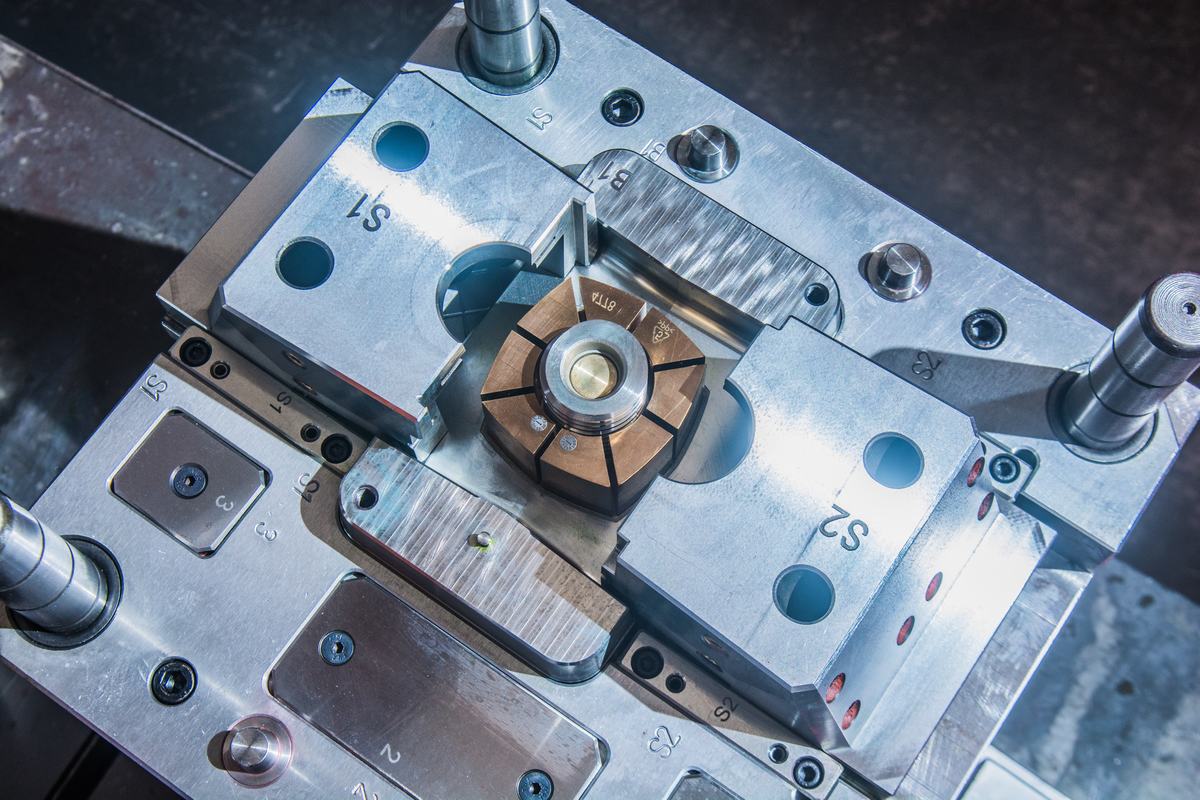

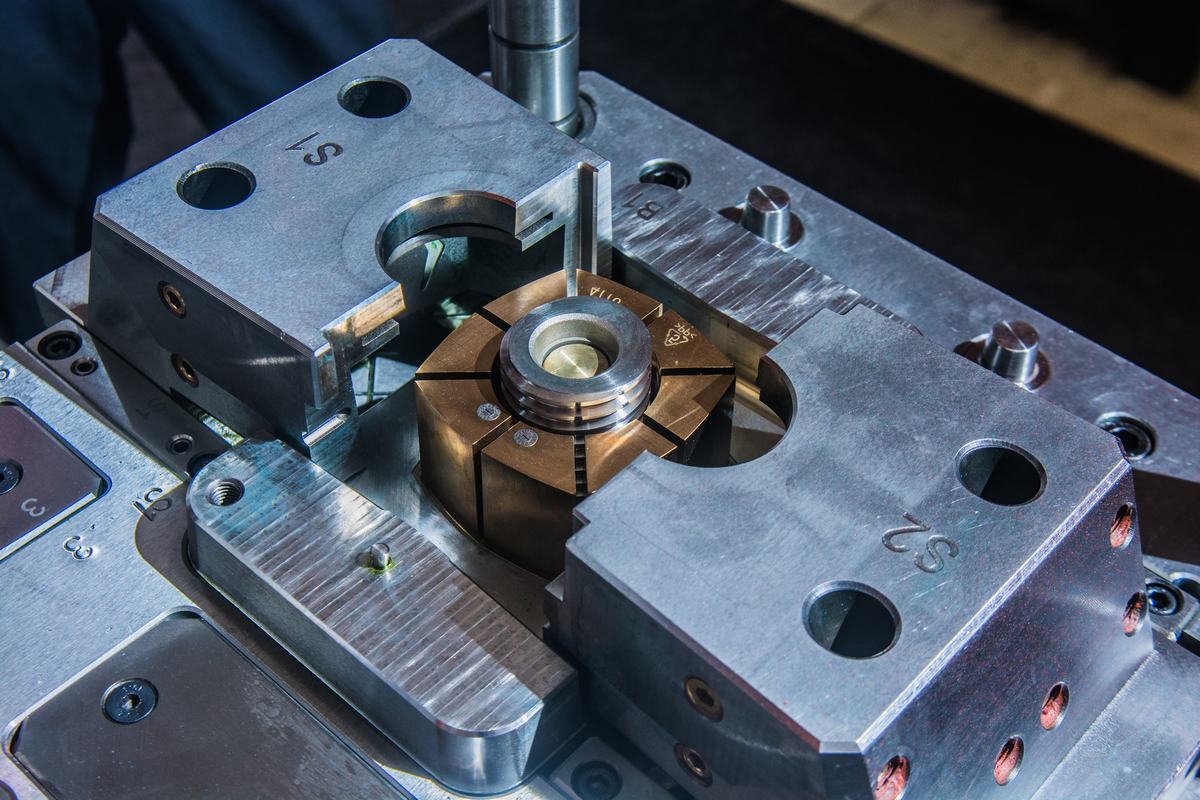

| Product Description | Automatic Unscrewing by rack and hydraulic jack,Bronze guide bush,good wear resistance and lubricity, to ensure the long stability of the mold during high-speed production, and to ensure the life of the mold.Good cooling,Using American Parker, Taiwan TWSNS and other high-quality hydraulic cylinders, air cylinders, reliable quality, long service life, no oil and air leakage. |

| Export country | Germany |

| Product Size | 80X80X47mm |

| Product weight | 76g |

| Material | PP GF30 Hostacom EKG2087 T Black |

| Finishing | charmilles 33 |

| Cavity Number | 1 |

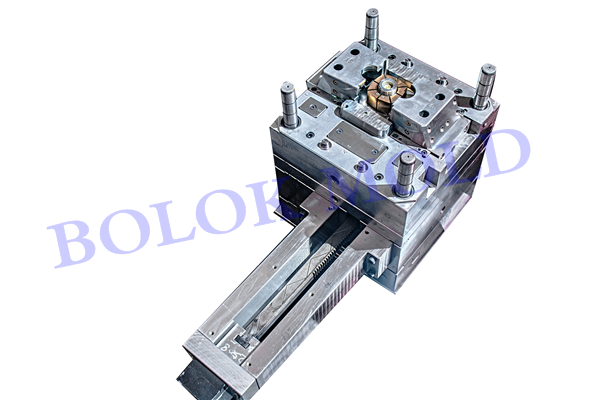

| Mold standard | Metric |

| Mold Size | 400X400X520MM |

| Steel | 1.2344 |

| Mold life | 1,000,000 |

| Injection | Cold runner Sub gate |

| Ejection | Automatic Unscrewing Ejectors |

| activity | 2 Sliders Automatic Unscrewing |

| Injection cycle | 55S |

| Product Features and Application | Automatic Unscrewing part, thread fits smoothly, |

Automatic Unscrewing by rack and hydraulic jack

Internal threads are commonly found on plastic parts that screw together, such as bottle caps, drinkware lids and plastic hardware. Due to the delicate nature of threads, molding these parts requires a slightly different approach than your average plastic part. An unscrewing core must be incorporated in the tool in order to eject them from the mold without damaging the threads.

In the past, these parts needed to be manually unscrewed from the core by hand to avoid stripping the threads. The additional labor and time it took to do this added to the part price and lead time. While many injection molding shops still follow this practice, we knew there had to be a better way.

Here’s How It Works:

First the plastic is injected into the tool. After the plastic has cooled, the threaded core starts to unscrew. The unscrewing mechanism works off of a rack and pinion and is powered by a hydraulic cylinder.

The rack turns three sets of gears which then retracts the threaded core into the ejector box.

Once the threaded core is fully unscrewed, the mold opens and the ejector system pushes a stripper plate forward to eject the part.

After the part is fully ejected, the hydraulic cylinder reverses, screwing the threaded core back into molding position and the process repeats.

Product detail pictures:

Related Product Guide:

Our goal is to provide high quality products at competitive prices, and top-notch service to customers around the world. We are ISO9001, CE, and GS certified and strictly adhere to their quality specifications for factory Outlets for Plastic Prototype Service - PP Copo plastic Molette pied F2 – Bolok Mold , The product will supply to all over the world, such as: Switzerland, panama, Mumbai, After years' creating and developing, with the advantages of trained qualified talents and rich marketing experience, outstanding achievements were gradually made. We get good reputation from the customers due to our good solutions quality and fine after-sale service. We sincerely wish to create a more prosperous and flourishing future together with all the friends home and abroad!

The customer service staff's answer is very meticulous, the most important is that the product quality is very good, and packaged carefully, shipped quickly!