18 Years Factory Parting Line Injection Molding - gas assist injection plastic broomstick – Bolok Mold

18 Years Factory Parting Line Injection Molding - gas assist injection plastic broomstick – Bolok Mold Detail:

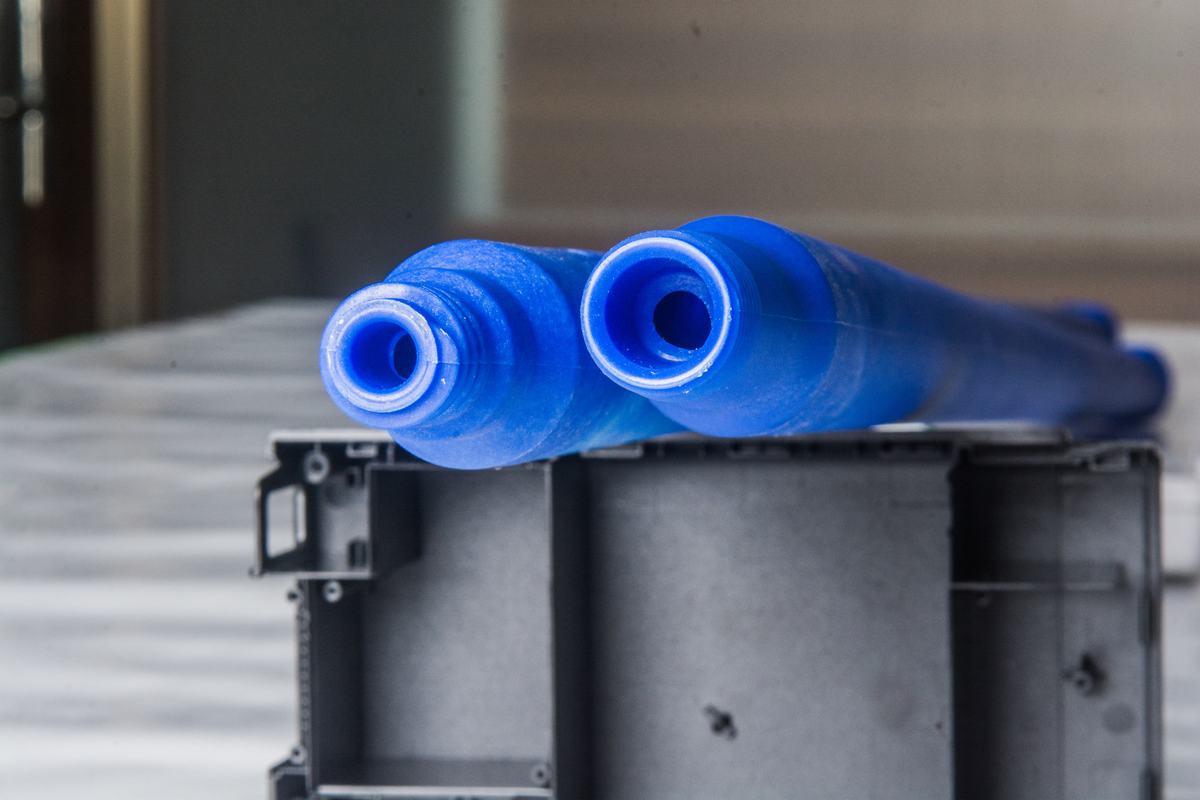

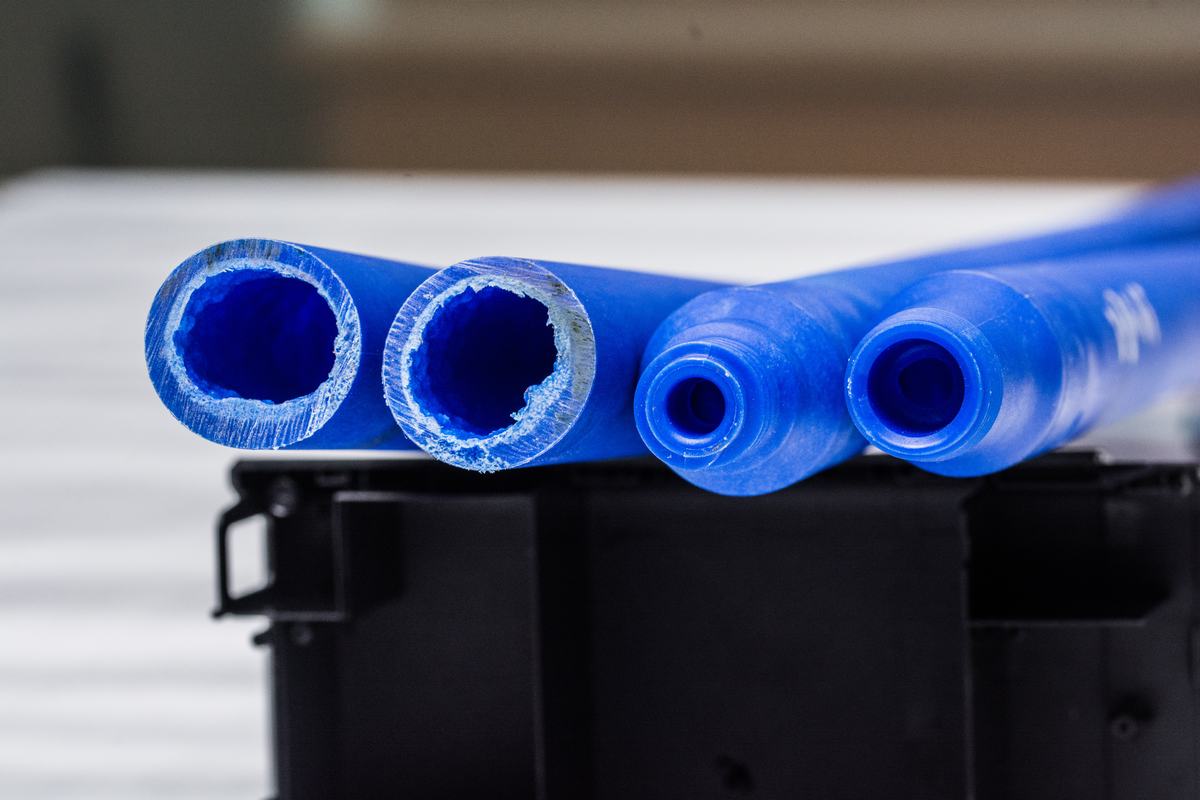

| Part Name | gas assist injection plastic broomstick |

| Product Description | We can offers both internal and external gas assist injection molding ,forces a short shot of material to fill a mold by using pressurized nitrogen gas to displace the material in pre-destined thick area while forming hollow sections in the part.The 1.8-meter-long product has no deformation, and the weight of the product is reduced by 80% compared with ordinary injection molding. |

| Export country | USA |

| Product Size | ∅24X1800 |

| Product weight | 300g |

| Material | PP GF20 |

| Finishing | Mirror polish |

| Cavity Number | 1+1 |

| Mold standard | HASCO |

| Mold Size | 500X2200X600MM |

| Steel | 1.2736 |

| Mold life | 500,000 |

| Injection | Incoe hot runner four vavle nozzles |

| Ejection | Ejection pin |

| activity | 2sliders |

| Injection cycle | 60S |

| Product Features and Application | By injecting a controlled stream of gas (nitrogen or carbon dioxide) into the mold, thick walls are created with hollow sections that save on material, shorten cycle time, and reduce the pressure required to mold the large plastic parts with complex designs and attractive surface finishes. All of these benefits are realized without any detriment to the structural integrity of the molded component. |

Product Details

This product is a part of Broomstick,Export to the United States.By injecting a controlled stream of gas (nitrogen or carbon dioxide) into the mold, thick walls are created with hollow sections that save on material, shorten cycle time, and reduce the pressure required to mold the large plastic parts with complex designs and attractive surface finishes. All of these benefits are realized without any detriment to the structural integrity of the molded component.

Product detail pictures:

Related Product Guide:

We believe in: Innovation is our soul and spirit. High-quality is our life. Consumer need to have is our God for 18 Years Factory Parting Line Injection Molding - gas assist injection plastic broomstick – Bolok Mold , The product will supply to all over the world, such as: Mauritius, Mauritius, Kazakhstan, We integrate design, manufacture and export together with more than 100 skillful workers, strict quality controlling system and experienced technology.We keep long term business relationships with wholesaler and distributors form more than 50 countries, such as USA, UK, Canada, Europe and Africa etc.

Speaking of this cooperation with the Chinese manufacturer, I just want to say"well dodne", we are very satisfied.

Write your message here and send it to us