Reprinted from micro injection molding

The exhaust of injection mold is an important problem in mold design, especially in rapid injection molding, the exhaust requirements of injection mold are more strict.

(1) The source of gas in the injection mold.

1) Air in the gating system and mold cavity.

2) Some raw materials contain water that has not been removed by drying. They are gasified into water vapor at high temperature.

3) The gas produced by the decomposition of some unstable plastics due to the high temperature during injection molding.

4) Why should the exhaust system be set for the gas injection mold generated by volatilization or mutual chemical reaction of some additives in plastic raw materials? Why should the exhaust system be set for the injection mold.

(2) Hazards of poor exhaust

The poor exhaust of injection mold will bring a series of hazards to the quality of plastic parts and many other aspects. The main performances are as follows:

1) In the process of injection molding, the melt will replace the gas in the cavity. If the gas is not discharged in time, it will make it difficult to fill the melt, resulting in insufficient injection volume and unable to fill the cavity.

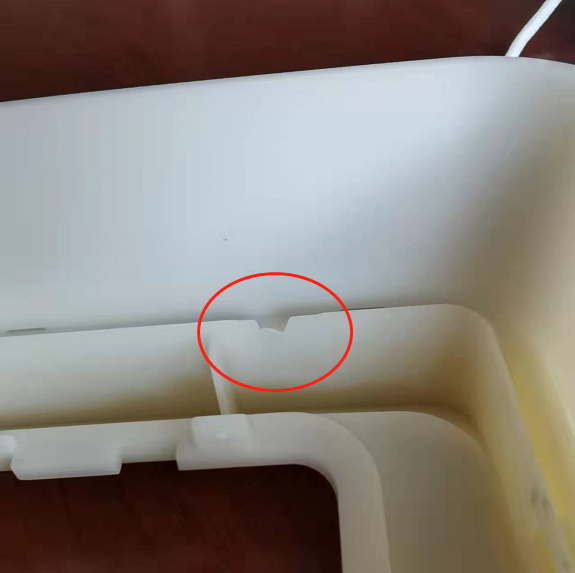

2) The gas with poor drainage will form high pressure in the mold cavity and penetrate into the plastic under a certain degree of compression, resulting in quality defects such as pores, cavities, loose tissue, crazing and so on.

3) Because the gas is highly compressed, the temperature in the mold cavity rises sharply, which leads to the decomposition and burning of the surrounding melt, resulting in local carbonization and charring of the plastic parts. It mainly appears at the confluence of two melts, * angle and gate flange.

4) The mechanical properties of each melt cavity are different, which makes it difficult for the melt to enter the mold and eliminate the weld mark.

5) Due to the obstruction of gas in the cavity, it will reduce the mold filling speed, affect the molding cycle and reduce the production efficiency.

(3) Distribution of bubbles in plastic parts

There are three main sources of gas in the cavity: the air accumulated in the cavity; Gas produced by decomposition in raw materials; The residual water and evaporated water vapor in the raw material have different positions of bubbles due to different sources. Why should the injection mold be equipped with exhaust system? Mold design.

1) The air bubbles generated by the accumulated air in the mold cavity are often distributed on the position opposite to the gate.

2) Bubbles generated by decomposition or chemical reaction in plastic raw materials are distributed along the thickness of plastic parts.

3) The bubbles generated by residual water gasification in plastic raw materials are irregularly distributed on the whole plastic part.

From the distribution of bubbles in the above plastic parts, we can not only judge the nature of bubbles, but also judge whether the exhaust part of the mold is correct and reliable.

Post time: Mar-23-2022