1.Definition: the structure of discharging and introducing gas into the injection mold.

2.Consequences of poor exhaust of injection mold: the products produce weld marks and bubbles, which are difficult to fill, easy to produce burrs (batch edges), the products are locally charred, there are bubbles inside the products, and the strength of the products decreases.

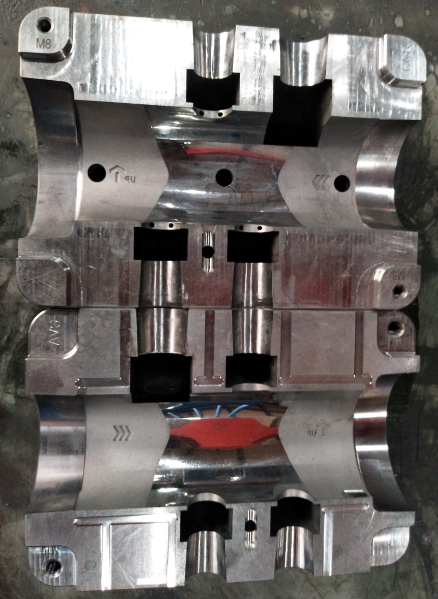

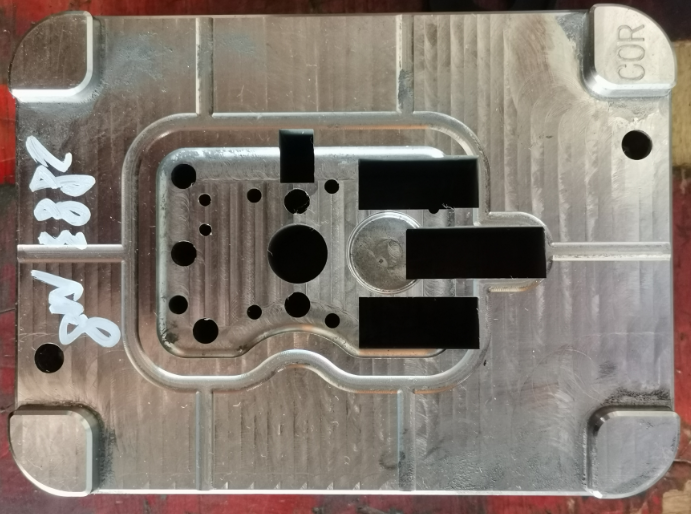

3.Exhaust method: the exhaust position of the exhaust slot shall be selected as far as possible at the parting surface and on one side of the cavity. Try to open it at the end of the material flow or at the confluence and at the thick wall of the product.

4.Design of exhaust slot: the exhaust slot shall be upward or downward as far as possible to avoid the operators. If it is impossible to avoid, the curved exhaust slot can be used. The depth dimension of the exhaust slot shall be less than the overflow value of the product, as shown in the table below:

The length of the exhaust slot is 5-10mm outward from the cavity, which is the primary exhaust slot. The secondary exhaust slot is deepened by 0.3-0.5. The width of exhaust slot is 5-25mm, generally taking the middle number of 5-12mm. Number and spacing of exhaust slots the spacing between the two exhaust slots is 8-10mm. Products with rough edges, such as gears, cannot be vented with exhaust slots. Use other exhaust methods, such as ejector pin, ejector rod, insert and so on.

Post time: Mar-23-2022